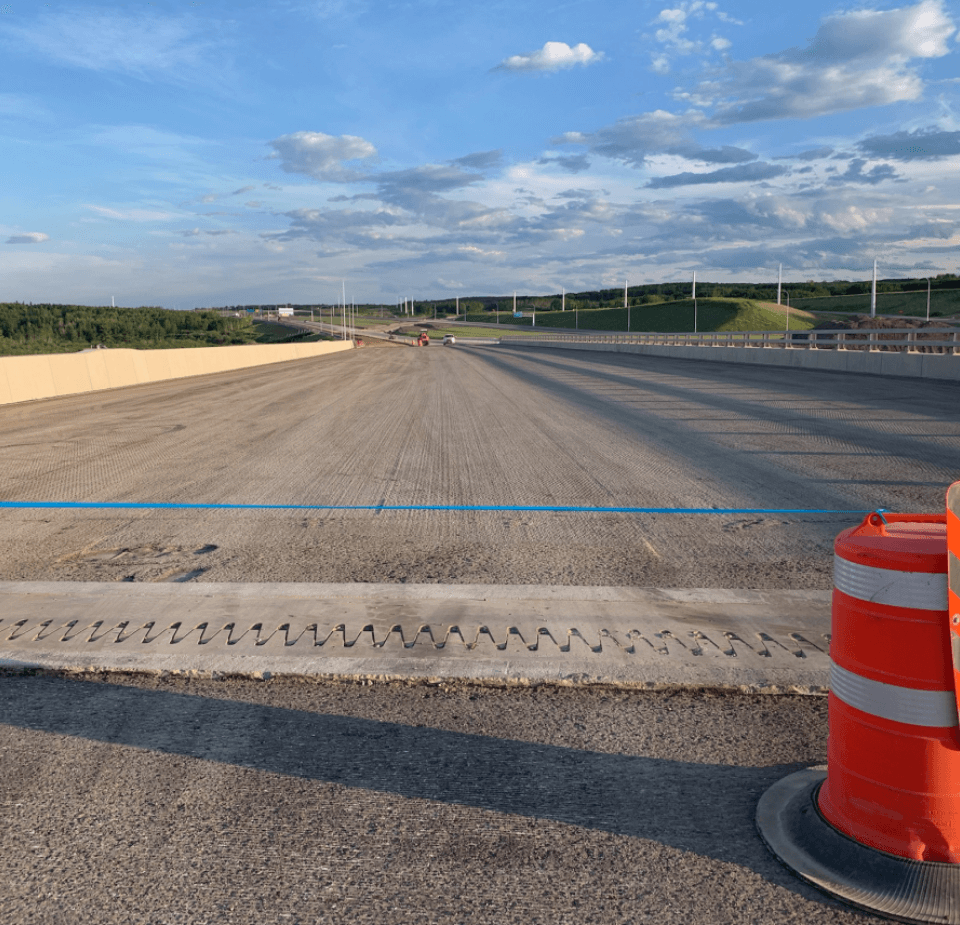

Delivering Specialized Asphalt Milling Services for All Applications.

We are Alberta’s most trusted asphalt milling experts since 1983.

We own an extensive fleet that consists of 15 milling machines, as well as an array of tractors, trailers, sweepers, trucks, skid steers, and sign equipment. These assets are expertly operated by a highly skilled and committed team, contributing to our reputation for unparalleled service delivery. All millings we produce are Recycled Asphalt..

We offer the following services for airports, highways (federal & provincial), city streets, municipalities, towns, bridges, parkades and driveways:

Established in 1983

Profile Grinding

Profile Grinding

We remove up to 3 inches of asphalt from the top surface layer to prepare the road or parking lot for an asphalt overlay.

Curbline Grinding

Curbline Grinding

We grind the curbline, lowering the roadway so that the new pavement can tie-end into the curb.

Pulverizing

Pulverizing

We grind and mix the existing asphalt section and underlying base or subgrade, leaving the material in place behind the grinder. This technique is generally used to recycle existing product and create a new sub-base product, or it can be used for a fill section.

Full Removal Grinding

Full Removal Grinding

We remove all asphalt from the road, which allows contractors to perform base work and utility work for their projects.

Slope Adjustment Grinding

Slope Adjustment Grinding

We can aid in addressing drainage concerns by shifting or increasing the crown of roads or parking lots to improve grade adjustments.

Saw Cutting

Saw Cutting

Using a specialized wheel on our milling machines, we cut the asphalt down to the base. This leaves the paving contractor with a clean, consistent edge to pave against for a road expansion.

Frozen Top Soil Removal

Frozen Top Soil Removal

In lieu of scrapers or backhoes, we use a milling machine to remove the desired depth of top soil. This technique can be performed in negative temperatures quickly and effectively.

Micro Milling

Micro Milling

We remove a thin layer (2 inches or less) of existing asphalt or concrete, leaving a finer texture. This removes the old, oxidized pavement and previous treatments to provide a more receptive bonding for new surface treatments.

Concrete Grinding

Concrete Grinding

We remove the top layers of concrete from roads, bridges, parking garages and other paved surfaces to create level, smooth surfaces that provide excellent traction for your construction project.

Crack Removal Grinding

Crack Removal Grinding

Where a crack is present, we mill out at least 50mm of asphalt, creating a reservoir large enough to be filled pre-overlay repair so that the crack doesn’t appear through the top lift.

Profile Grinding

Profile Grinding

We remove up to 3 inches of asphalt from the top surface layer to prepare the road or parking lot for an asphalt overlay.

Curbline Grinding

Curbline Grinding

We grind the curbline, lowering the roadway so that the new pavement can tie-end into the curb.

Pulverizing

Pulverizing

We grind and mix the existing asphalt section and underlying base or subgrade, leaving the material in place behind the grinder. This technique is generally used to recycle existing product and create a new sub-base product, or it can be used for a fill section.

Full Removal Grinding

Full Removal Grinding

We remove all asphalt from the road, which allows contractors to perform base work and utility work for their projects.

Slope Adjustment Grinding

Slope Adjustment Grinding

We can aid in addressing drainage concerns by shifting or increasing the crown of roads or parking lots to improve grade adjustments.

Saw Cutting

Saw Cutting

Using a specialized wheel on our milling machines, we cut the asphalt down to the base. This leaves the paving contractor with a clean, consistent edge to pave against for a road expansion.

Frozen Top Soil Removal

Frozen Top Soil Removal

In lieu of scrapers or backhoes, we use a milling machine to remove the desired depth of top soil. This technique can be performed in negative temperatures quickly and effectively.

Micro Milling

Micro Milling

We remove a thin layer (2 inches or less) of existing asphalt or concrete, leaving a finer texture. This removes the old, oxidized pavement and previous treatments to provide a more receptive bonding for new surface treatments.

Concrete Grinding

Concrete Grinding

We remove the top layers of concrete from roads, bridges, parking garages and other paved surfaces to create level, smooth surfaces that provide excellent traction for your construction project.

Crack Removal Grinding

Crack Removal Grinding

Where a crack is present, we mill out at least 50mm of asphalt, creating a reservoir large enough to be filled pre-overlay repair so that the crack doesn’t appear through the top lift.

Ready To Get Started On Your Next Project?

For the most trusted asphalt milling services in Alberta, call us today at (403) 938-7088 or submit our inquire form below.